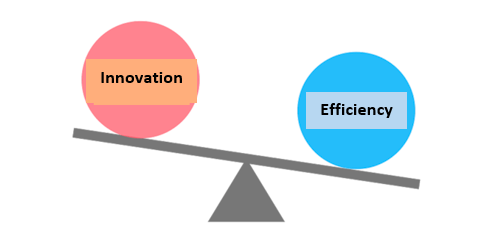

Balancing innovation and efficiency can be devilishly tricky. Just ask 3M.

If you ask any business leader whether they should invest in innovation or efficiency in their company they’ll probably tell you “well, we should do both!”. And they’re right. Companies need innovation. New products and services are the lifeblood of growth. However, companies also need to learn to be execution machines that can produce these products and services in a highly efficient manner, otherwise they’ll fail to make money.

But balancing innovation and efficiency can be devilishly tricky. Just ask 3M.

A Cautionary Tale: The Rise and Fall of 3M as an Innovation Powerhouse

For most of its 100+ year history, 3M was one of the darlings of Wall Street. By any metric it was considered one of the world’s most consistently innovative companies. The company was producing up to 3,000 new patents per year including an incredible range of groundbreaking inventions (everything from Scotch Tape and Post-It Notes to Medical Equipment and items used for NASA space missions). By the early 1990’s working at 3M was considered one of the best jobs a young aspiring professional could hope to get.

By the late 1990’s though, things had changed. The company had become sluggish and its stock price was languishing. People began to whisper that 3M had lost its magic touch. 3M’s board of directors were desperate to get back onto the rocket-like trajectory they had been on.

The Board’s plan to rejuvenate the company culminated in hiring a “superhero CEO”: Jim McNerney, one of the top executives at General Electric (GE), which was considered by many to be the most efficiently run Fortune 500 company in the world at the time.

3M’s board considered McNerney a huge prize. The company’s stock jumped nearly 20% when his selection as CEO was announced. Everyone was convinced that McNerney was going to lead 3M back to the promised land.

The primary reason McNerney was so valued was his ability to import GE’s world-famous Lean Six-Sigma program into 3M’s operations.

Like what you’re reading? Help us share the Unwritten Business guide with others!

Lean-Six Sigma: The Machine that Changed the World

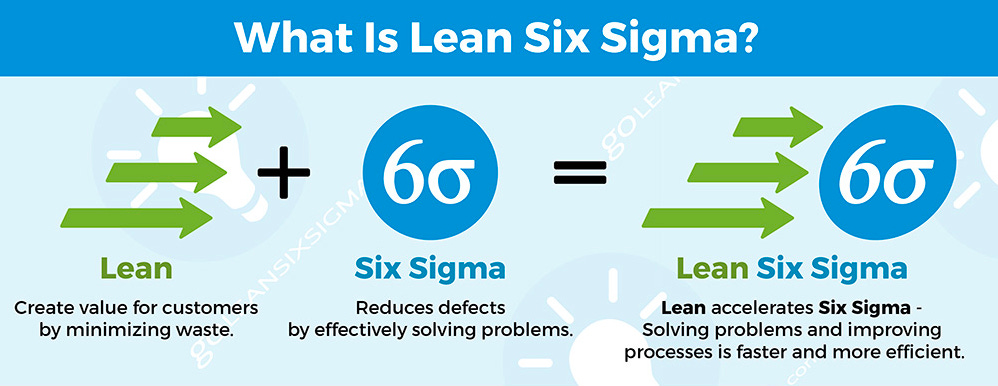

For those who aren’t familiar, Lean Six Sigma (“LSS” for short) is a management philosophy and set of tools that has 2 main goals:

- Improve the flow of the production system

- Reduce all waste (aka muda) and variability from production

LSS does this through kaizen, a process of achieving small and continuous improvements. Think of it as the 1% improvement rule, but applied to business. If a step in a process isn’t deemed to be adding value to a customer, people figure out ways to eliminate that step (ex: having a product sit in a warehouse, spending time adding features customers don’t really use, etc.)

When done right, LSS usually results in improved product quality, bottom-line costs, improved production capacity, safer work environments, and faster customer lead times which create an enormous competitive advantage for a company.

In fact, the reason LSS originally became extremely extremely popular was because it was the system that Toyota (and other Japanese automakers) used to completely disrupt the “big 3” American automakers (Ford, Chrysler, and GM) during the 1980’s and 90’s.

Simply put, Lean Six Sigma is one of the most powerful “operation execution” tools in business. It’s sometimes called the “Machine that Changed the World”. And it was exactly what 3M wanted to bring inside its own 4 walls.

What Happened Next at 3M: When Efficiency Kills Creativity

Fulfilling his campaign promises, newly minted 3M CEO Jim McNerney immediately implemented GE’s famous LSS process. Thousands of 3M employees quickly became certified “Lean Six Sigma Black Belts” (masters of the six sigma craft). Cost cutting and waste elimination efforts were put on high intensity. Production lines were put under scrutiny, and dozens of major process improvement efforts were funded.

At first the plan appeared to work. McNerney’s LSS program gave a jolt to 3M’s stagnant stock price. The company garnered praise from the media for its “new and efficient model”. It seemed like the superstar CEO did indeed have the magic touch.

But after McNerney abruptly left 3M only 4.5 years later to take an even more prestigious job at Boeing, people started to wonder if 3M had paid too high a price for its “new and efficient model”.

3M had changed dramatically. It was definitely efficient, but everyone noticed that the number of breakthrough R&D inventions had drastically declined. 3M researchers reported mounting frustrations at getting funding for new ideas slashed due to their “waste”.

Other employees complained of a one-size-fits all Lean Six Sigma approach that didn’t work for R&D (ex: many of the cost cutting goals that made perfect sense for the production lines didn’t make sense when applied to the new products lab)

By 2007 the company had fallen off the list of virtually every innovation ranking in the world. Stockholders began to fret about the company’s longevity if it could no longer reliably produce new innovations.

Ever since, it has served as a cautionary tale of the consequences of sacrificing innovation at the altar of efficiency.

So why did this happen?

In a nutshell: Short term financial incentives > long term financial incentives

Put yourselves in the shoes of an executive who just finished implementing a successful LSS system. Your reward for all this effort? A bunch of cost savings!

You then have to decide what to do with all of this new cash. Do you (A) invest it into a new product idea that may or may not pan out, or (B) invest it into even more operations improvements which have a pretty guaranteed ROI and will make your CEO and investors extremely happy?

If you chose option B, you’re like most managers.

The short-term incentives can be extremely hard to ignore. That is one of the primary reasons why operational improvement efforts (like Lean Six Sigma) often take precedence over longer-term investment into riskier ventures like new products.

Finding the Right Efficiency/Innovation Balance…

So is there any hope for business leaders looking to balance two necessary but seemingly incompatible forces? Yes, but it’s hard. Extremely hard.

Fortunately there are a few strategies that have proven successful in the past:

Strategy #1 – Outsource Innovation

One strategy is to simply outsource innovations to independent third-party R&D centers, especially in instances where there are high risks and development costs associated with the new product design, both of which tend to be viewed as “waste”.

The outsourcing strategy is most effective for companies in an industry where technology progress speed is high and demand is increasing at a dramatic rate.

However, too much outsourcing of innovation capabilities can be dangerous to a company’s long-term competitiveness since they may ultimately lose the ability to develop any internal product innovations on their own.

Strategy #2 – Establish an Independent Innovation Center

If a company worries about losing their “innovation muscle” by outsourcing, they can set up what is sometimes called an “independent innovation center”. This means that you set up a separate department (sometimes even a separate company!) that has the mission of coming up with growth producing innovations for the company.

Ideas coming from the Innovation Center are tested, prototyped, and experimented on repeatedly until product-market fit is found. Once you’ve identified a winning product, you bring it back into the “mothership” company and apply all the benefits of a Lean production system to it. This way you get the best of both worlds.

The trick here is independence. Innovation Centers only work if they run off a completely separate budget that is purposely protected by management. Leadership has to accept that innovation is a messy process that requires constant experimentation (and the dollars that go with it). If you don’t keep the Innovation Center separately funded, it becomes all too easy for a COO or CFO to start looking at R&D expenses as prime targets for cost-cutting measures.

Closing Thoughts

Figuring out how to balance a company’s innovation capabilities and making the company a “lean machine” is a delicate dance. But it’s one that every strategist needs to grapple with. A company has to learn to simultaneously think of its long term growth and its short-to-mid term operations if it’s to be successful.

Finding the answer question requires not only a long term mindset, but also the best creativity we can muster.

PS: If you’re interested in the nitty-gritty details of the innovation vs. Lean Six Sigma problem, I actually spent 3 years writing a thesis paper on the topic (link here). It’s one of my favorite problems to wrestle with when I’m working with executive teams on corporate strategy.