Find the “slowest hiker” in your operation. Then lighten their pack. The payoff is enormous.

There’s a strange paradox in business operations: if you let the slowest person set the pace for the entire team, you’ll actually be more successful than letting everyone run at their full speed.

Let me explain.

The Legend of “Herbie”

In the legendary business operations book “The Goal” (by Eliahu Goldratt), Alex Rogo is a fictional factory manager who is faced with the seemingly impossible task of turning his small town’s failing production plant around in less than 3 months.

Desperate for help, Alex seeks the help of a professor who tells him he can make incredible progress if he can find and eliminate the plant’s “constraints” (constraints = obstacles/bottlenecks holding up the entire assembly line). The professor warns him that he could literally improve everything else in the factory but if he doesn’t fix the bottlenecks none of his other improvements will matter.

In the middle of trying to figure out what this advice even means, Alex is asked to be the scoutmaster for his son + his group of friends on a weekend hike to a nearby lake. As scoutmaster, Alex is responsible for making sure all the kids make it to the campsite on time and as a group. If you’ve ever tried to keep a group of young boys all together on a trip you can probably predict what happened next.

Alex simply can’t keep everyone together. Despite his repeated reminders to “stick together as a group”, the group keeps getting spread out along the trail. Large gaps, sometimes miles long, appear between the boys. Alex realizes this is because some of the boys hike really fast and others go really slow. One boy in particular, Herbie, is the slowest hiker of them all and always lags behind.

At first Alex tries to solve the problem by repeatedly asking the fast hikers in the front to wait up for the slower hikers. This works okay for a few minutes, but the moment they start walking again the same gaps appear.

That’s when Alex has a revelation: The purpose of the hike is not to see which hiker can get to the campsite fastest; the goal is to get to the campsite all together as a team. They have to move as a single unit (a system), instead of as individuals.

After this insight Alex decides to try something different. Rather than let the fastest boys go first he puts the slowest hiker in the troop (Herbie) first in line and gives strict orders that no one can pass him on the trail. Even though it’s counterintuitive to have your slowest person set the pace, Alex immediately notices that the troop suddenly has the ability to stay together (no more gaps in the line!). Every boy can keep up with the boy in front of him.

The upside of this approach is that Alex can keep an eye on the whole group at once and knows they will arrive safely at the campsite all at the same time. The downside is that they are all moving at Herbie’s pace so they will get there late.

Alex realizes that if he wants the group (the whole system) to move faster he has to help Herbie (the bottleneck) move faster. Since Herbie is setting the pace, any improvement to his speed, no matter how small, will make the entire group move more quickly.

To help Herbie move faster Alex decides to lighten his load. They take the items in Herbie’s heavy backpack and distribute them among the rest of the troop. With a lighter pack Herbie is able to move 2X as fast and the whole group easily makes it to their lake-side campsite on time!

On the drive home, Alex thinks about how this same approach could help him save his production plant. Instead of trying to improve every part of the operation all he needs to do is identify “the Herbie” (the bottleneck), the machine that is the slowest part of the assembly line. If he can figure out how to make that machine run faster / more efficiently he can improve the output of his entire factory.

If you like this article (so far) please feel free to share it with someone. We’d love your help in growing the “Unwritten Business Guide”

How Do You Identify Bottlenecks?

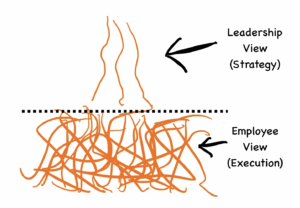

Finding bottlenecks in your own business is actually fairly straightforward. You simply need to look for the gaps (the places where the hikers are spread out too far along the trail).

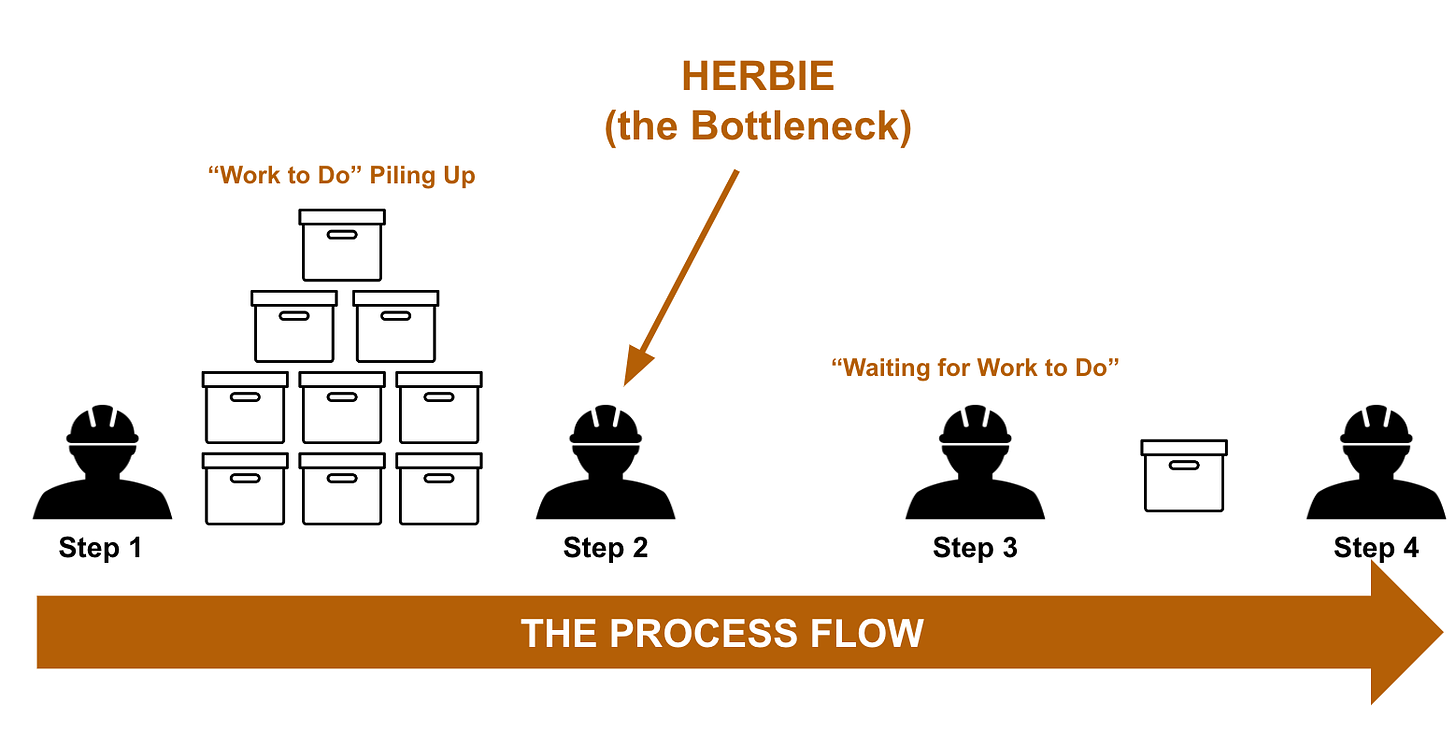

Think of an assembly line in a factory. If you saw a machine that had a TON of work piling up in front of it + noticed that the machine just after it was always waiting for work to do, that would be a tell-tale sign that you’ve found a “Herbie”. It’s a machine that simply can’t process things fast enough and thus is starving downstream steps of work to do.

The same principle applies even if you don’t work in manufacturing. Every business (including tech or service industries) has processes & workflows. Think of all the steps it takes to complete a sales process or onboard a customer. Just like an assembly line in a factory there will be places where people are always complaining of “waiting for XYZ data to arrive” or “having too much to do”. These are the gaps you’re looking for.

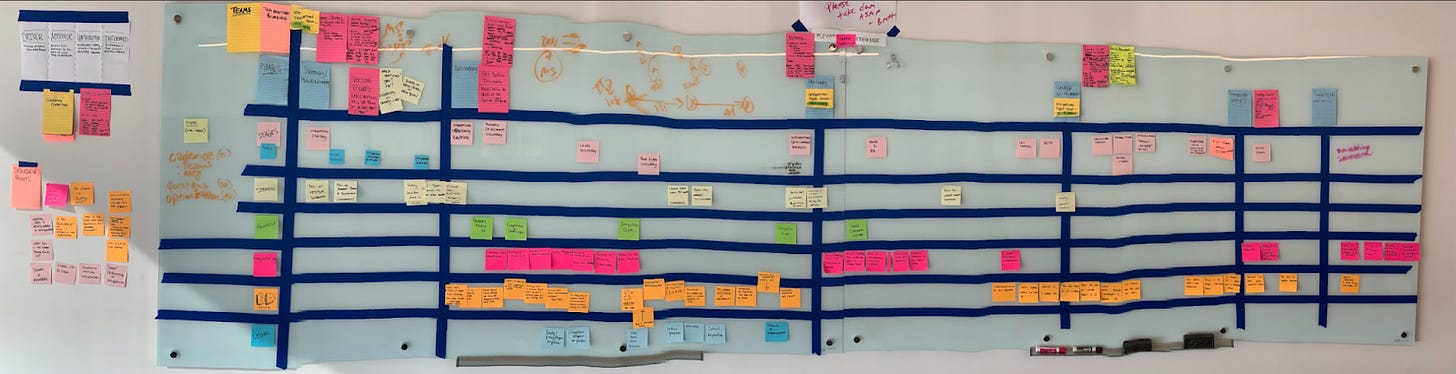

One of the best methods for identifying gaps is to conduct what I call a “Kaizen Workshop”. This involves mapping out a process end-to-end on a wall. Each sticky note indicates a step in the process. After you get the steps in place, you then ask the group to identify (usually with a bright neon sticker) where work always seems to get bogged down or piles up. Those “pain areas” are very likely to be bottlenecks hiding in plain sight.

So I found “Herbie” in my operations. Now what do I do?

Once you’ve identified a “Herbie” in your system you need to “lighten his pack” (aka, help him move more quickly).

Earlier we mentioned that the “bottleneck determines the pace for the entire system”. This point is so important that it can’t be emphasized enough. If you don’t help your “Herbie” move faster almost nothing else you do will matter. If your “bottleneck” can only move at 2 mph then your entire business can only move at 2 mph (even if you have other parts with the capacity to move at 100 mph).

Because the Bottleneck is so crucial, there are 2 major principles you need to keep in mind:

Principle #1: Make sure the Bottleneck’s time is never wasted

Every minute “Herbie” spends doing something other than getting critical work done is a minute the entire operation loses. So you can’t afford to have Herbie waste time.

What does a “bottleneck wasting time look like?”

- Being idle during breaks

- Processing parts that are already defective or handled sloppily

- Working on things that aren’t being currently demanded/needed by things downstream

- Working on stuff that doesn’t matter

- Shutting down / going on vacation / getting sick / being out of commission

- Etc…

How do you prevent a bottleneck from wasting time?

- Implement Quality Assurance: Make sure that anything the “bottleneck” is going to work on is 100% mistake free. You don’t want your “Herbie” spending time on something only to catch a mistake and then have to send it back for re-work. Implement a quality assurance check on any work before it is sent over to the bottleneck to be worked on.

- Don’t Send Your Bottleneck Trivial Tasks: Don’t send things to the bottleneck that aren’t important. For example, If your bottleneck is a key employee don’t have them be the one spending hours formatting the PowerPoint deck. If your bottleneck is a specific machine don’t have it work on parts that aren’t critical.

- Keep the Bottleneck Healthy/Happy: Like keeping Herbie energized/hydrated on the mountain trail, you can’t afford for your bottleneck to break down or burn out. Make sure key employees are being taken care of (emotionally, financially, mentally, physically). Make sure key machines are regularly repaired and put on a preventative maintenance schedule.

- Have a Backup: What are you going to do if your “Herbie” needs to go on vacation? This literally happened to me at a company I worked at. We had a key member of our business development team go on paternity leave. Everyone started panicking when they realized literally no one else at the company could do his job. Suddenly a huge part of our company’s go-to-market pipeline was at risk. Don’t let this happen to you. Cross-train people on how to do the “bottleneck” job. Buy a backup machine. Make sure that your bottleneck person/machine has some redundancy (ex: a backup plan should your key employee/machine stop working). You need to have a plan if your bottleneck decides to take a well-deserved break.

Principle #2: Lighten the Bottleneck’s Load

Alex the Scoutmaster realized that the key to making Herbie hike faster was to help him not carry so much weight in his backpack. You need to do the same for your bottleneck.

Look for ways to “lighten the backpack” your bottleneck is carrying:

- “Do all of these parts have to be produced by this machine? Or can we use other machines to do this?”

- “Could we re-assign some of our key employee’s tasks to other team members?”

- “Could we buy another machine that can do the same work as our “Herbie”?

- “Could we hire another team member to add some capacity to this “bottleneck” step?”

- “Is that report actually necessary? Or can we stop asking XYZ to spend time on it?”

- “Could we outsource this work to another company?”

- Etc…

Finding “Herbie” in your personal life…

One of my favorite things about business theory is how it can readily be applied to our personal lives as well. Take a look at your own life or job and apply the Theory of Constraints:

- What is my Goal?

- Identify the “Herbie” that is slowing down progress towards that Goal

- Find ways to make “Herbie” move faster or eliminate the “Herbie” altogether

One of my favorite examples of this in practice comes from Greg McKeown (author of “Essentialism”). He shared a personal experience in applying the “Theory of Constraints” to his personal life that I found very relatable:

“When our children were really little and I was at graduate school, my wife was feeling strained by the demands of looking after the children all day every day, and didn’t know quite what to do about it. I was reading about the Theory of Constraints at the time so it was particularly on my mind…. We realized that the primary obstacle keeping her from making her highest point of contribution in our children’s lives was a lack of time to plan, think, and prepare; after all, with three little children it was nearly impossible to have uninterrupted time.

So we worked to remove this obstacle. I opted out of many of the extracurricular activities to be home in the evenings and we found someone who would look after the children for a few hours during the week. As a result, we were able to be more fully engaged and present during the time we spent with our children. In other words, we both actually ended up doing less, but better.”

I’ve used this same approach to lighten my load at work, get critical projects done, and more recently spend more time with my wife and children. There are processes everywhere you look.

Find your own “Herbie” and “lighten his pack”. The payoff is enormous.